Driving Improvement at the Point of Impact

-

Boost Operational Efficiency

-

Customized Lean Solutions

-

Engaged, Empowered Workforce

-

Sustainable Growth and Profitability

-

Expert Lean Guidance

We've had the pleasure of working with some amazing companies!

Why Lean Applications?

We combine deep industry knowledge with practical, actionable strategies

Choosing Lean Applications means partnering with a team that understands the intricacies of your industry and has the expertise to drive meaningful change.

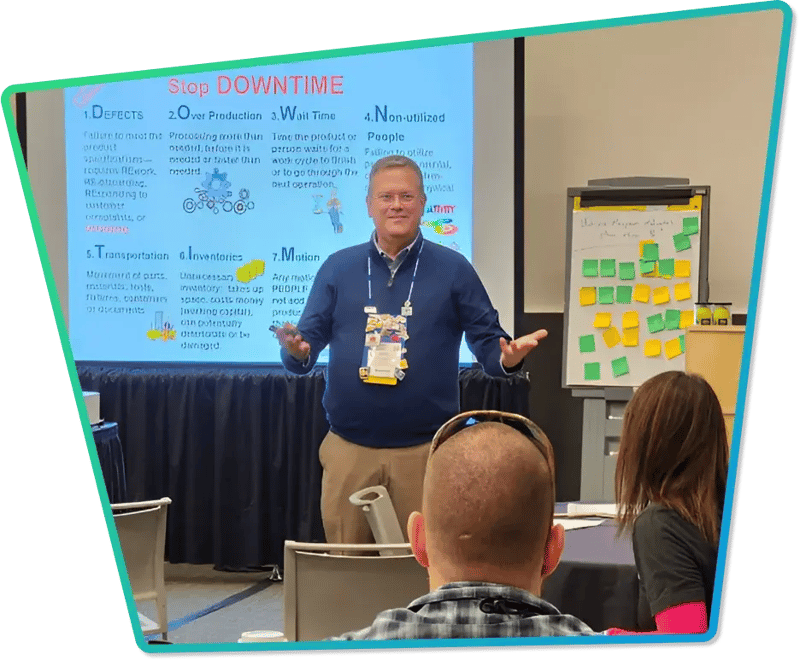

With over 25 years of experience in manufacturing and healthcare, our founder, Mark Preston, has honed a unique approach that combines proven lean methodologies with hands-on coaching and leadership development. We don’t just implement tools; we transform cultures, empowering your workforce to continuously improve, innovate, and excel.

-

Cultural Transformation

-

Leadership Development

-

Improved Customer Satisfaction

-

Strategic Innovation

Our Approach

Empowering Your Workforce in a Changing Industry

We understand the unique challenges that today’s manufacturers face, from high turnover and skill shortages to an aging workforce. Our approach is designed to address these issues head-on by empowering and inspiring your team to drive meaningful and sustainable organizational improvements.

Through personal coaching and mentoring, we engage your workforce at every level, ensuring they are motivated, skilled, and connected to your company’s vision.

- Engagement and Inspiration

- Tailored Tools and Training

- Sustainable Transformation

- Continuous Support

Unlocking the Potential Within Your Team

We believe that change starts with people. By working closely with your leadership, we help inspire and engage your workforce with a clear sense of purpose, driving alignment between individual roles and company goals.

Customized Solutions for Your Unique Challenges

Our hands-on training and tailored tools empower your leaders to implement effective, engaging, and lasting changes. We combine proven methodologies like Value Stream Mapping and Gemba Leadership to foster a dynamic culture of improvement.

Building a Lasting Foundation for Success

We’re committed to creating long-term, sustainable success. Through our comprehensive approach, we help you build a model of excellence that extends across your organization and sets the stage for continuous growth.

Ensuring Your Progress Stands the Test of Time

Our partnership goes beyond implementation. We provide ongoing support to ensure the improvements we’ve introduced become ingrained in your daily operations, delivering lasting results that propel your business forward.

OUR SERVICES

Let's Create a Model of Excellence

With unique tools and training, we will teach your leaders how to implement positive changes with hands-on approaches that are fun, educational, and impactful.

Lean Assessment

The Lean Enterprise Assessment is your starting point that will provide a thorough understanding of your situation and goals. We will put together a customized plan, combining classroom training with application, designed to help make the improvements necessary to drive your company toward excellence

Continuous Improvement

Continuous Improvement is a constant journey but like in every trip, we need a destination along the journey. What are the goals and objectives of the system? How do we measure the progress of the Continuous improvement system? How do we communicate our progress?

A3 Problem Solving

Problem Solving by everyone in an organization is the core of any Lean Enterprise culture. Kaizen is the ability to understand the problem and apply problem-solving techniques in pursuit of perfection.

Value Stream Mapping

Value Stream Mapping is a powerful Lean tool that plays a crucial role in the pursuit of operational excellence. By visually mapping out every step of a process, it helps organizations identify inefficiencies, waste, and areas for improvement. This comprehensive overview enables teams to streamline operations, enhance product flow, and align resources more effectively.

Daily Management and Gemba Leadership

Effective implementation of lean manufacturing requires engagement, understanding, ownership, and creative thinking by everyone in that operation. Going to the gemba isn’t enough. How do you go to the gemba? What do you look for once you get there? What do you do?

Visual Management

Implementing Visual Management techniques is essential for any Lean Enterprise. It is critical for long-term sustainability. Visual Management is much more than posting process-related metrics. It will drive daily management and continuous improvement.

Discover More Ways We Can Support Your Success

What people are saying

"Mark is an expert in lean and people systems because he has lived them himself. Mark's consulting and teaching style leverages his past experiences (both good and bad) so that others can learn from real situations. The impact he has made on organizations he has mentored is enviable. His practical and experience-based approach makes him one of the best in the business."

Eric Kulikowski

Senior Director of Supply Chain Optimization (Retired)

What people are saying

"Mark is a talented leader with a passion for creating world-class operations. His methods and training provide a focused yet engaging environment. His common sense approach to solving problems creates buy-in throughout all levels of the organization. I consider Mark to be an expert in the field of TPS and Supply Chain excellence, and enjoyed working with him all over the world."

Cory Resler

Vice President, Operations and Supply Chain

What people are saying

"Mark is an visionary Lean Leader with one of the best hands-on experience I have seen in action in the industry and has the ability to transfer knowledge at the speed of light. I have met several Lean practitioners from the Nafta region but Mark is definitely the "heads and shoulders" from them all. His extensive product experience, exposure to very different managerial styles and cultures makes him a unique consultant."

Javier Chinchilla

Plant Manager

What people are saying

"Mark is a pleasure to work with. He is detailed oriented Director and he always made you feel part of the team and was always in good spirits to help in anyway and was very thorough in his directions during the implementation of Lean Manufacturing in EVCO Plastics de Mexico. Mark had a strong background and training in Lean Manufacturing, he was always able to execute his plans and continually attained or exceeded operational goals. He had excellent people skills demonstrated by managing a diverse work group in functional background and ethnicities."

Luis Cantu

SHEQ Manager

Our Latest