Business Lean Tools

Extend Lean Principles Across Your Entire Organization

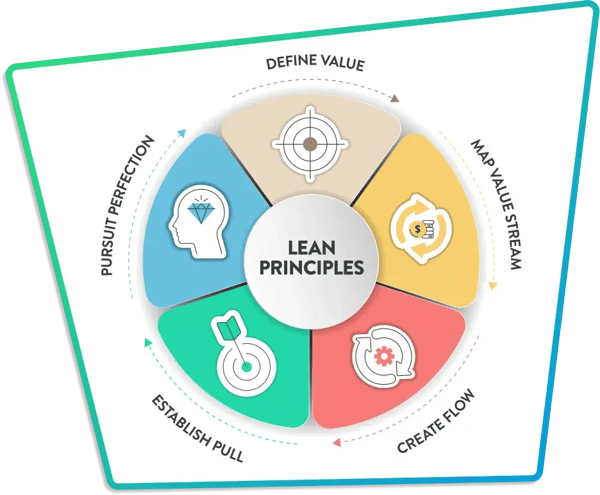

With our business lean tools, lean methodologies are integrated into every corner of your business operations. Whether enhancing your lean office or improving supplier relations through Lean practices, these solutions align your entire organization towards efficiency and superior quality.

Solutions

Business Lean Tools

- Lean Office Training

- Lean Playbook Creation Workshop

- Project Management Workshop

- Supplier Development Workshop

- Lean in Sales

Overview

Lean Office Training

Lean Office Training focuses on equipping participants with the knowledge and skills needed to create effective Office Playbooks. This hands-on workshop teaches the application of Lean principles in the office environment, emphasizing the reduction of waste, improvement of processes, and the creation of standardized work. Through exercises and practice, participants will develop the tools necessary to implement Lean practices that drive efficiency and continuous improvement within their teams.

Benefits

- Streamlined Training: Simplify the onboarding and training of new workers with clear, standardized processes.

- Reduced Variability: Document and standardize office processes to minimize variation and improve consistency.

- Foundation for Improvement: Establish a solid base for continuous improvement initiatives within the office environment.

- Enhanced Visual Management: Implement process-level visual management to track progress and identify opportunities for further improvement.

Learning Objectives

- Explain the 8 wastes in the office and their impact on efficiency.

- Demonstrate how Lean applications can directly improve job performance.

- Create a SIPOC (Suppliers, Inputs, Processes, Outputs, and Customers) for their job and team.

- Develop process maps for key office processes.

- Build a Playbook to guide their team’s operations.

- Apply Visual Management techniques to identify opportunities and drive systematic improvements.

Overview

Lean Department Playbook Creation Workshop

The Lean Department Playbook Creation workshop is designed to help teams improve their internal and external customer relationships by eliminating waste and creating a structured approach to continuous improvement. This workshop focuses on defining key metrics, creating a team playbook, and driving alignment within the team to achieve consistent improvements.

Benefits

- Creation of a Playbook: Establish a standardized playbook that guides team processes and improvement efforts.

- Process Improvement: Develop a structured process for ongoing team improvement.

- Key Metrics and 90-Day Plan: Define key performance metrics and create a 90-day plan for continuous improvement.

- Alignment and Visual Management: Ensure that the entire team is aligned and utilizing visual management techniques for better performance tracking.

Learning Objectives

- Understand Critical Concepts for Improvement.

- Create a SIPOC (Suppliers, Inputs, Process, Outputs, and Customers) for their team.

- Develop a Table of Contents for the team’s playbook.

- Create a unique playbook for the team’s processes and approaches.

- Establish Key Performance Indicators (KPIs) that drive results using visual management.

Overview

Project Management Workshop

The Project Management Workshop - DMAIC is designed to review best practices in project management, focusing on the DMAIC (Define, Measure, Analyze, Improve, Control) methodology. This course provides project managers with the structure, templates, and tools needed to achieve successful results in their projects. The workshop emphasizes the application of lean principles to enhance productivity, oversee progress, and drive performance, while also preparing project leaders to excel in communication and team leadership.

Benefits

- Lean Application in Project Management: Learn how to effectively apply lean principles within the project management domain.

- Complementary Concepts: Understand how lean principles can complement and enhance traditional project management practices.

- DMAIC Methodology: Gain a thorough understanding of the DMAIC approach to project management.

- Path to Success: Learn the steps from project chartering to achieving return on investment (ROI).

- Tailored Project Structure: Discover how to choose the right project structure based on the specific characteristics of the project.

Learning Objectives

- Apply lean principles in the context of project management.

- Recognize the complementary relationship between lean principles and traditional project management concepts.

- Understand and implement the DMAIC approach to project management.

- Chart a clear path from project initiation (charter) to successful project completion (ROI).

- Determine the appropriate project structure based on the nature and needs of the project.

Overview

Supplier Development Workshop

The Supplier Development Workshop is designed to help companies establish strong, collaborative partnerships with their strategic suppliers by implementing a detailed 13-week Supplier Development Program (SDP). This program focuses on applying lean practices and continuous improvement methodologies to enhance supplier operations, ultimately benefiting both the supplier and the company. Through this workshop, participants will learn how to apply lean methodologies, create a continuous improvement culture, and improve overall supplier performance.

Benefits

- Improved Supply Chain Visibility: Enhances transparency across the supply chain, allowing for better management and coordination.

- Inventory Reduction: Reduces cross-supply chain inventory, leading to cost savings and increased efficiency.

- Improved Product and Process Quality: Enhances the quality of products and processes, leading to better customer satisfaction.

- Improved Customer Service Levels: Boosts the ability to meet customer needs effectively.

- Increased Productivity: Streamlines operations, leading to improved productivity for both the supplier and the company.

- Enhanced Communication: Facilitates better communication between suppliers and the company, fostering a more collaborative environment.

- Collaborative In-Depth Product Knowledge: Encourages knowledge sharing and collaboration, leading to better product development and innovation.

Learning Objectives

- Identify and assess strategic suppliers.

- Understand and apply lean principles to supplier operations.

- Develop and implement a detailed methodology and plan (toolkit) for the Supplier Development Program.

- Utilize Gemba to identify opportunities for improvement.

- Help suppliers implement lean practices and establish a continuous improvement culture.

- Assist suppliers in improving quality and reducing costs.

- Develop and implement employee involvement teams at the supplier level.

- Review and learn from case studies of successful Supplier Development Program implementations.

Overview

Lean in Sales Workshop

The Lean in Sales Workshop focuses on applying lean principles to improve sales processes by aligning strategies with tactics, reducing waste, and enhancing customer value. By leveraging lean tools and methodologies, sales teams can streamline their processes, better manage their time, and ultimately drive higher revenue and customer satisfaction. This workshop equips sales professionals with structured and repeatable methods to achieve consistent sales growth.

Benefits

- Alignment of Strategy and Tactics: Ensures that sales strategies are effectively executed through aligned tactics.

- Process Improvement: Facilitates the creation of a streamlined sales process that supports continuous improvement.

- Enhanced Sales Growth: Provides tools and techniques to drive consistent sales growth.

- Time Optimization: Identifies gaps in time usage, enabling sales teams to spend more time engaging with customers.

- Visual Management: Offers the ability to see sales pipelines visually, leading to better tracking and management of sales efforts.

Learning Objectives

- Understand critical concepts for sales process improvement.

- Create a SIPOC (Suppliers, Inputs, Process, Outputs, Customers) for improving sales team functions.

- Map out processes that support sales growth.

- Develop a unique playbook for improving sales processes and approaches.

- Utilize visual management techniques to monitor sales pipelines.

- Establish key performance indicators (KPIs) for sales that directly contribute to results.